-40%

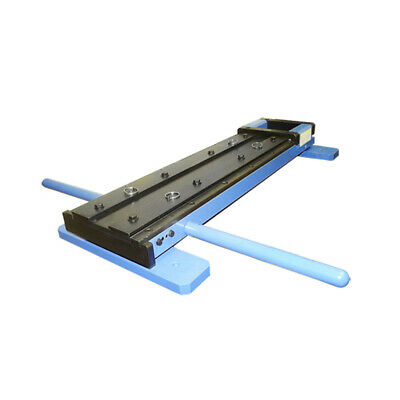

Upgraded Acrylic Lightbox Plastic PVC Bending Machine Heater Acrylic Bender 220V

$ 360.09

- Description

- Size Guide

Description

Upgraded Acrylic Lightbox Plastic PVC Bending Machine Heater Acrylic Bender 220VDescription:

This Acrylic Plastic PVC Bending Machine is increasingly used in school technological innovation course, decoration projects, packing of square columns or wall corners, fish tank, window edge, display counter, supermarket shelves, advertising light box, art products making, etc.

Decoration industry: Acrylic bending side, acrylic display rack, acrylic decoration bending, etc.

Industry: safety guard on machinery, protective cover for production line, production line exhibition stand, storage box, etc.

Feature:

1.Humanized design, easy operation, and convenient use.

2.Advanced infrared heating technology with circulating water cooling system, adjustable temperature.

3.Adjustable heating surface of material, with scale to guarantee heating surface’s accuracy, conformity, ensure good bending effect.

4.Evenly heated, instantly shaped, no deformation, no scorch, no foaming.

5.Instant forming, temperature adjustable; Water circulating cooling system equipped

Specification:

Model: ABM700

Theory: Thermal forming

Maximum Bending Width: 650mm

Applicable thickness: 1-10mm

Voltage:

AC 220V/50HZ

Power: 800W

Temperature range: 0-600°C Adjustable

Product size: 38.9" x 28.7" x 3.9" (990 x 750 x 100mm)

Net weight: 19KG

Package size: 50" x 17.2" x 8.4" (1250 x 430 x 210mm)

Gross weight: 25KG

Installation:

1. Put the main machine on a stable table

2. Insert the plug.

3. Insert two water tubes, one end of tube with copper insert stick into the water pump. The other head of both tube stick into the copper joints on the main machine.

4. 20L volume bucket or water tank, fill up with water, fix the water pump to the bottom of bucket/ tank.

Operation:

1. Insert the plugs of water pump and main machine, turn on heating switch. The heating rod starts heating, cooling water starts to circulate.

2. Adjust the proper temperature according to the plate material and thickness, also adjust the heating surface controller gap to appropriate size.

3. Wait until the heating tube get red, put the material onto the worktable to heat, make sure the material just above the heating tube.

4. Bend the soft material promptly to any angle you want, cool for a while.

5. Finish, turn off the heating switch, then the pump.